Bamboo Lyocell: What is it and why is it an important difference?

Share

You may already have some bamboo fabrics in your wardrobe and you may already know how amazing this fabric can be. But did you know that there are different ways to make fabric from bamboo - the most common requiring the need for heavily corrosive chemicals baths?

Bamboo fabric is making a large impact on the textile and fashion world as the next big thing. Bamboo is easy to grow, it's great at absorbing carbon from our atmosphere, it's highly renewable and it has amazing qualities when turned into a fabric. The potential for bamboo to replace many common and resource intensive materials, such as cotton and polyester, is very real and as we move forward into the next decade it wont be surprising that you start to hear about it and see it more.

But what makes one bamboo fabric different from another bamboo fabric?

Quite a lot actually. This article will dive into the differences between them.

Processes, Chemicals and Compounds

Bamboo fabric is created by following some basic steps.

First, you need to grow it. Luckily, as the worlds fastest growing plant, it doesn't take long to do this. Bamboo can reach full maturity within 3-5 years and only needs to be cut at the base to be harvested - no uprooting necessary. This process is helpful in many ways. It makes it easy to harvest for farmers and by leaving the root system in tact, you can help repair and stabilize degradated soil.

Once it's grown and and harvested, you need to crush it up into pulp. Bamboo fabric comes the cellulose of the bamboo plant. In order to get this cellulose, you need to extract it from the pulp and there are two ways to do this.

This is where bamboo fabrics differ.

There are currently two main ways to extract the cellulose from bamboo pulp. One involves an extremely corrosive compound call Sodium Hydroxide and the other uses an organic compound called an amine oxide. Can you guess which uses what?

Viscose/Rayon

First, lets talk about Bamboo from Viscose/Rayon.

This is the most common type of bamboo fabric you will find on the market. If you have any bamboo fabric in your wardrobe, take a look at the tag and see if it falls into this category. It may say Bamboo Viscose or Bamboo from Rayon, but these are two of the same.

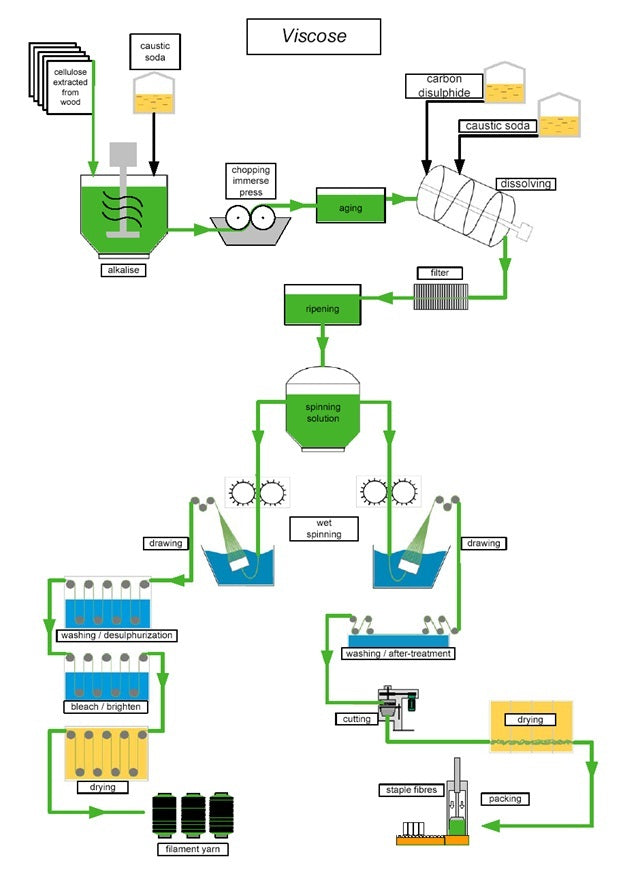

The production method used to make these fabrics involves using Sodium Hydroxide to extract the cellulose from the pulp by soaking it in a caustic soda bath. From there, the pulp is pressed to remove as much of the caustic soda as possible. This is left to dry, at which point Carbon Disulfide (a colourless neurotoxic volatile liquid) is added to the mix, left to evaporate and change the texture of the product. One last bath in Sodium Hydroxide is used to refine the product and then it is spun through small nozzles into a hardening solution usually consisting of diluted sulfuric acid or bleach.

As you can see, there are many steps involved and many different harsh chemicals used in this production method.

Another aspect to consider is how these chemicals are disposed of after use. Many of them are corrosive if mishandled and can easily contaminate fresh water if not disposed of properly.

Bamboo Lyocell

Bamboo Lyocell fabric comes from a production method that uses a closed loop system and an organic solvent to create a fiber from the cellulose of the bamboo plant. When compared to the commonly used viscose method of making fabric from bamboo, you can start to understand how most bamboo fabrics are not as green as they claim.

Bamboo is naturally pest resistant so herbicides and pesticides are not needed in order to make it grow well. This means organic bamboo is grown easily and we're already saving precious groundwater.

Once the bamboo is first crushed up into pulp, its dissolved in an organic compound (NMMO) that turns the pulp into a high viscosity solution.

From there the thick solution is filtered to remove large chunks.

From there it's spun through an air gap spinneret to create the fibers and is washed. The residual NMMO is recovered and recycled.

Finally it is finished, dried and ready to be made into the most comfortable fabric you can imagine.

Don't wrap yourself up in a chemical cloth

It's good to know the difference between cheaply made fabrics and sensibly made fabrics. There is a HUGE difference between bamboo fabrics so don't be fooled by cheap brands that try to sell you Environmentally Friendly Bamboo Viscose sheets... Because there's just no such thing.

Click Here to Check Out Truly Organic and Naturally Bamboo Bedding Today